Here's Newsweek back in October, 2021: "#BareShelvesBiden Becomes Top Trend on Twitter Amid Supply Chain Crisis". For some reason the three-syllable hashtag has been replaced by the less euphonious #EmptyShelvesBiden but the point is the same: the logistics crisis was not fixed for Christmas, and it is about to get worse.

On January 15 Canada will require cross-border truckers to have proof of vaccination against covid-19.

That will be followed on January 22 by the U.S. requiring the same.

Here's a December 1, 2021 letter from the President of the Private Motor Truck Council of

Canada to a half-dozen Canadian and American regulators:

December 1, 2021

Subject: Canadian and United States of America land border vaccination mandates for essential workers

I hope this communication finds you well. I am writing on behalf of the membership of the Private Motor Truck Council of Canada. The PMTC is the only National Association in Canada that represents the views and interests of Canada’s Private and dedicated carriers. The PMTC was founded in 1977. Private Trucking represents an estimated 50% of the class 8 trucks on the road in Canada today, and roughly 70% of the smaller urban delivery vehicle market.

The purpose of our communication today is to express our concerns over the border vaccination mandates for essential workers, set to take effect in January of 2022 for essential workers crossing land borders into Canada and the US. (coming into effect on January 15th for non-residents entering Canada, and rumoured to be taking effect January 22nd for non-residents entering the United States of America)

Our concerns are that this policy will cause severe shortages in an already depleted workforce, on both sides of the border.....

....MUCH MORE (3page PDF)

That follows on the testimony of Chris Spear President and CEO of the American Trucking Association, November 17, 2021:

Before the

House Committee on Transportation & Infrastructure

United States House of Representatives

Hearing on

“Industry and Labor Perspectives: A Further Look at North

American Supply Chain Challenges”

If interested, here is one of our posts on transportation/logistics:

Sometimes people forget where their food comes from and who it is they should thank for their daily sustenance.

One of the things a risk manager is tasked with is catastrophizing possible futures and developing plans to either mitigate or hopefully, profit from the worst case scenario. Most of our readers are familiar with the more dramatic scenarios: Tokyo earthquake at magnitude 8.5 - 9.5. An electromagnetic pulse, whether caused by a coronal mass ejection or an airburst of a nuclear weapon, an underwater landslide on the order of the Storegga slide creating a megatsunami, etc. These are the better known risks.

But one of the more mundane risks is something like a general strike.

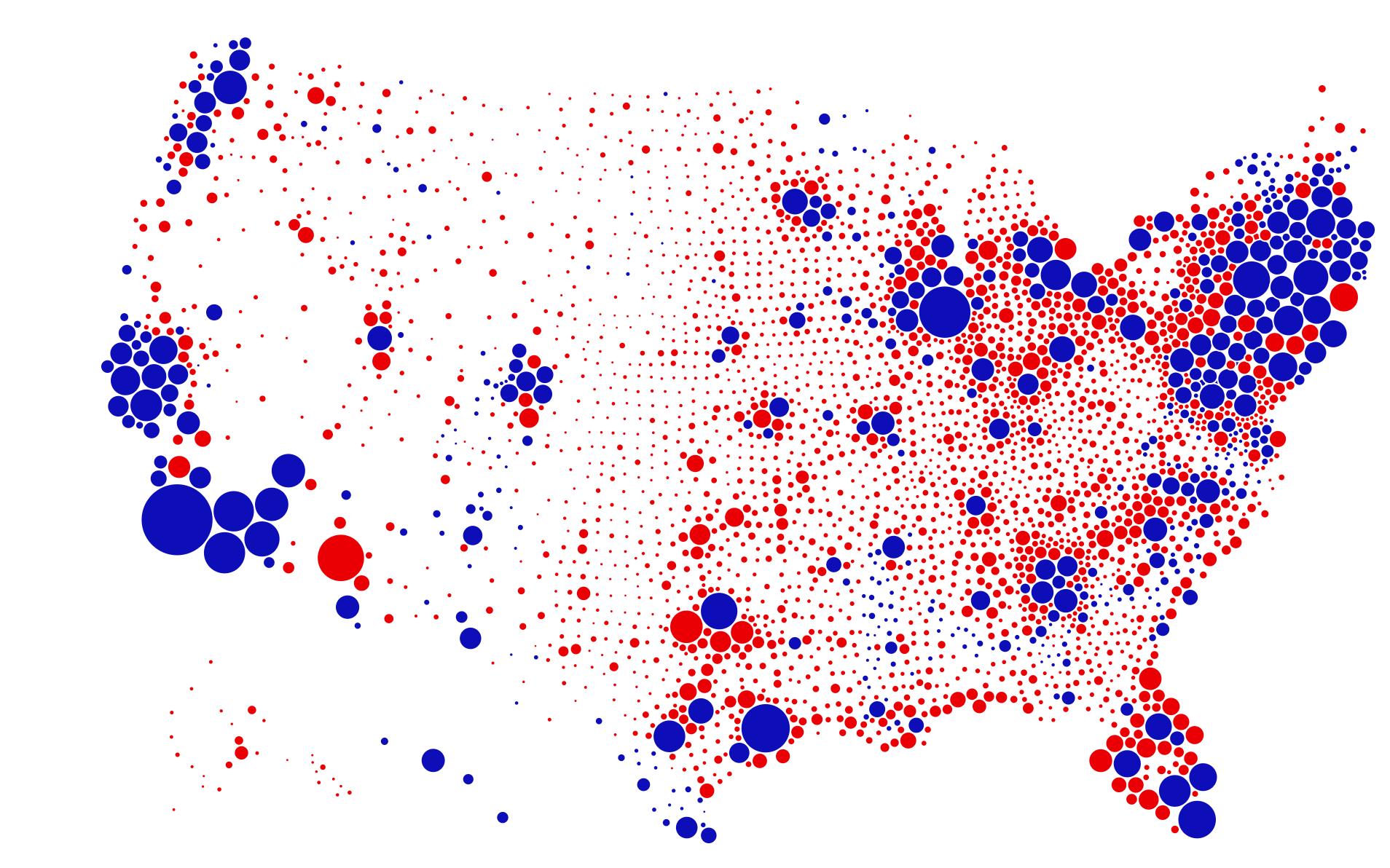

Here's a map used to make the political point that land doesn't vote, people vote:

What the map also does is highlight the places, cities, that would be most at risk if the whole system came to a halt.

How long would it take for the food supply to run out in New York City or San Francisco or Atlanta or Philadelphia?

Here's the American Trucking Association with some answers:

When Trucks Stop, America Stops

Commercial truck traffic is vital to our nation’s economic prosperity and plays a significant role in mitigating adverse economic effects during a national or regional emergency. Our economy depends on trucks to deliver ten billion tons of virtually every commodity consumed—over 80 percent of all freight transported annually in the U.S. In the U.S. alone, this accounts for $700.4 billion worth of goods transported by truck. Trucks hauled 65.6% of the shipment of value into Canada and 67% of the shipment of value into Mexico.It becomes apparent that any disruption in truck traffic will lead to rapid economic instability.

The unimpeded flow of trucks is critical to the safety and well-being of all Americans. However, it is entirely possible that well-intended public officials may instinctively halt or severely restrict truck traffic in response to an incident of national or regional significance.

History has shown us the consequences that result from a major disruption in truck travel. Immediately following the 9/11 terrorist attacks, significant truck delays at the Canadian border crossings shut down several auto manufacturing plants in Michigan because just-in-time parts were not delivered. The economic cost to these companies was enormous. Following Hurricane Katrina, trucks loaded with emergency goods were rerouted, creating lengthy delays in delivering urgently needed supplies to the stricken areas.

Although in the face of an elevated threat level, a terrorist attack, or a pandemic, halting truck traffic may appear to be the best defense, it actually puts citizens at risk. Officials at every level of government must recognize that a decision to halt or severely curb truck traffic following a national or regional emergency will produce unintended health and economic consequences not only for the community they seek to protect, but for the entire nation.

The American Trucking Associations researched seven key consumer industries to quantify the potential consequences of restricting or halting truck traffic in response to a national or regional emergency. This report details the findings.

The Food Industry

Every day, Americans purchase billions of dollars of groceries. Most of these goods are brought to market via daily truck deliveries. •Significant shortages will occur in as little as three days, especially for perishable items following a national emergency and a ban on truck traffic.Minor shortages will occur within one to two days. At convenience stores and other small retailers with less inventory, shortages will occur much sooner.

•Consumer fear and panic will exacerbate shortages. The forecast of a winter storm quickly exhausts basic commodities at grocery stores and supermarkets. It takes retailers up to three days to recover from these runs on supplies. News of a truck stoppage—whether on the local level, state or regional level, or nationwide—will spur hoarding and drastic increases in consumer purchases of essential goods.Shortages will materialize quickly and could lead to civil unrest.

•Supplies of clean drinking water will run dry in two to four weeks. According to the American Water Works Association, Americans drink more than one billion glasses of tap water per day. For safety and security reasons, most water supply plants maintain a larger inventory of supplies than the typical business. However, the amount of chemical storage varies significantly and is site specific. According to the Chlorine Institute, most water treatment facilities receive chlorine in cylinders (150 pounds and one ton cylinders) that are delivered by motor carriers. On average, trucks deliver purification chemicals to water supply plants every seven to 14 days. Without these chemicals, water cannot be purified and made safe for drinking. Without truck deliveries of purification chemicals, water supply plants will run out of drinkable water in 14 to 28 days. Once the water supply is drained, water will be deemed safe for drinking only when boiled. Lack of clean drinking water will lead to increased gastrointestinal and other illnesses, further taxing an already weakened healthcare system.

Healthcare

Both healthcare providers and consumers rely on regular delivery of medications and healthcare supplies to hospitals, pharmacies, nursing homes and other healthcare facilities. Trucks deliver nearly all of these supplies. Al Cook, former president of the Materials Management Association and current member of the Medical Materials Coordinating Group, which is advising the U.S. Department of Health and Human Resources on emergency preparedness, describes over-the-road commercial transportation as “life and death to being able to care for sick people.”

•Without truck transportation, patient care within the truck stoppage zone will be immediately jeopardized. According to Cook, many hospitals have moved to a just-in-time inventory system. In fact, some work from a low-unit-of-measure system.This means that essential basic supplies, such as syringes and catheters, are not ordered until the supplies are depleted. These systems depend on trucks to deliver needed supplies within hours of order placement. Internal redistribution of supplies in hospitals could forestall a crisis for a short time; however, in a matter of hours,hospitals would be unable to supply critical patient care.

•If an incident of national significance produces mass injuries, truck transportation is the key to delivering urgently needed medical supplies necessary to save lives. According to Cook, there are not enough medical supplies in any local area to support a large scale medical emergency. The Medical Materials Coordinating Group has worked with U.S. Health and Human Services to develop contingency plans that will coordinate national redistribution of essential medical supplies during a national emergency.

These contingency plans ensure that affected areas receive adequate medical supplies to support the crisis while also maintaining adequate supplies for the basic medical needs of the larger community. Cook states that the medical redistribution program relies on trucks as the primary mode of transport to carry out the expedient redistribution of supplies, and ties the success of the program to the ability of trucks to access medical facilities and warehouses during an emergency situation.

•Hospitals and nursing homes will exhaust food supplies in as little as 24 hours.Hospitals and nursing homes receive daily truck deliveries of food for patients. The International Food Distributors Association notes that because these facilities lack significant warehousing capabilities, a truck stoppage will result in food shortages within 24 to 48 hours, particularly among perishable items.

•Pharmacy stocks of prescription drugs will be depleted quickly. Although pharmacies typically carry several weeks inventory of many drugs, seasonal pharmaceuticals, such as antibiotics and flu-shots during winter months, have faster turnover rates. According to the National Association of Chain Drug Stores, most of the nation’s 55,000 drug stores receive daily merchandise deliveries by truck.

•Hospitals and other diagnostic and treatment facilities will exhaust supplies of radiopharmaceuticals and oxygen. Radiopharmaceutical supplies for cancer treatment and diagnostic services, which have an effective life of only a few hours,will become unusable. Hospital size and storage capacity determine the amount of oxygen a facility can maintain; however, in general, hospitals will exhaust oxygen supplies within seven to ten days....

....MUCH MORE

And those are just the logistics. Moving further back up the supply chain you have the packagers and preparers, and the physical food and other supply traders and so on back to farmers and other people who root around in the dirt. As has been said: "If it's not grown, it's mined."

Something to think about. And maybe plan for.

Since they've had months to prepare for this I am sure the governments of Canada and the U.S. have a well-thought-out plan in place for this eventuality.

Probably in the file next to the CDC's covid response plan.