(much) Smarter minds than mine have looked at this conundrum and came to the conclusion that increasing productivity in construction is hard.

From Construction Physics, May 4.

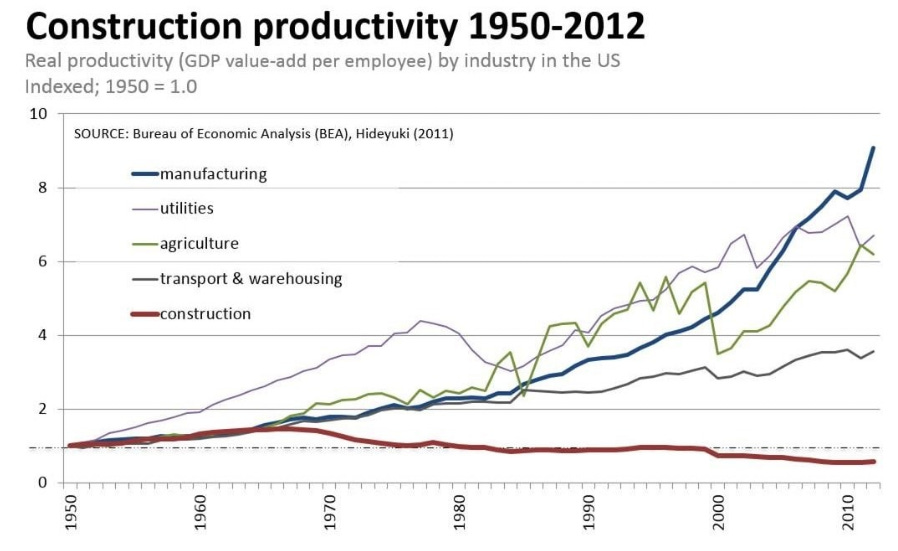

We talk a lot around here about construction being an inefficient industry. Whereas other industries have shown increasing productivity over time, construction has remained flat or even declined. There is no shortage of depressing graphs showing this:

But these productivity measures are fairly abstract and high-level. They identify the problem, but don’t give many clues as to what the solution might be. So it’s worth drilling down into the mechanisms that underlie a production process, and understand exactly what has gone wrong in an inefficient one.

A Simple Production Model

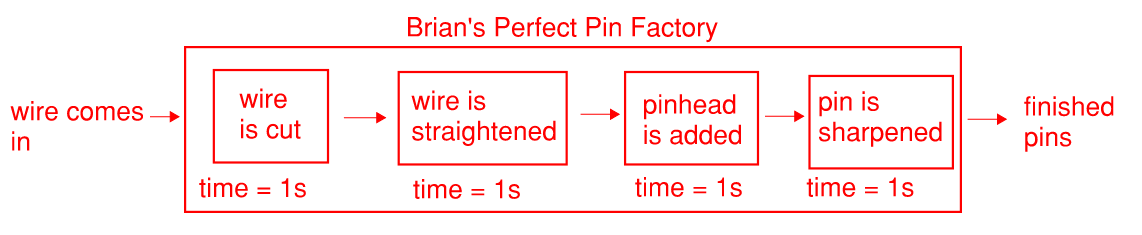

In the grand tradition of Adam Smith, let’s consider a simple pin factory. In our factory, coils of wire come in on one end, get processed at a series of workstations, and come out the other side as finished pins. In this simplified model, the manufacturing process has 4 discrete steps:

Cutting - a piece of wire is cut off from the coil.

Straightening - the piece of wire is straightened.

Attaching head - the head of the pin is attached to the body.

Sharpening - the end of the pin is sharpened.

For simplicity, we’ll assume each step in the process takes exactly one second. With this, we can calculate a few different measures of the production process:

The factory’s production rate, or throughput, is one pin per second.

The factory’s work-in-process, the amount of partially completed work currently in the system, is always 4 pins (one at each station).

The factory’s cycle time, the time it takes a pin to go through the factory, is 4 seconds (one second for each of the 4 stations).

The equipment’s utilization rate is all 100% - every station is in use at all times.

The queue length at each station is zero - pins don’t spend any time in the process waiting for a piece of equipment to become available.

These metrics tell us how efficient our production process is. More efficient factories will produce more (higher production rate), produce faster (lower cycle time), and hold as little inventory as possible (lower work-in-process).

Our example pin factory is actually a perfectly efficient production process - assuming the times and process arrangement are fixed, the production rate is as high as possible, and the cycle time and work-in-process are as low as possible. The reason it’s so efficient is that there’s no waiting anywhere in this system - as soon as a pin is done with one step of the process, it can immediately proceed to the next step.

But real life production processes almost never move in perfect lockstep like this. In particular, they often have a significant amount of variation in them. This can be anything from natural process variation (it might take between 10 and 15 minutes for a task to complete), to random equipment breakdown, to occasional production errors that need to be reworked.

So let’s look at a slightly modified version of our pin factory, with a bit of variance injected into it. Instead of each step taking exactly 1 second, each step now takes on average one second, but is distributed normally with a standard deviation of 0.5 seconds.....

....MUCH MORE

I mean sure, the use of heavy machinery led to massive gains in what one person could accomplish.

And as pointed out in "Construction Used to Be More Labor Intensive (and other pictures you may not have seen before) CMB":

This link is pretty much the definition of eclectic.

From Messy Nessy Chic:

In the Grand Scheme of Things

As you can imagine, I collect a lot of images from the internet. And sometimes, I need to unload them to clear some space on the old laptop. So this is me, doing that, in a meaningful way. I hope you’ll find the theme of today’s spring clean larger than life…

....MUCH MORE

But overall, the efficiency gains have been hard-won.