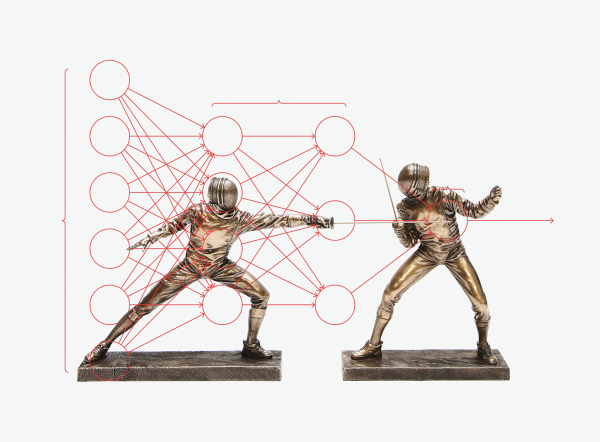

Dueling neural networks.

Artificial embryos. AI in the cloud. Welcome to our annual list of the

10 technology advances we think will shape the way we work and live now

and for years to come.

Every year since 2001 we’ve picked what we call the 10 Breakthrough Technologies. People often ask, what exactly do you mean by “breakthrough”? It’s a reasonable question—some of our picks haven’t yet reached widespread use, while others may be on the cusp of becoming commercially available. What we’re really looking for is a technology, or perhaps even a collection of technologies, that will have a profound effect on our lives.1.

For this year, a new technique in artificial intelligence called GANs is giving machines imagination; artificial embryos, despite some thorny ethical constraints, are redefining how life can be created and are opening a research window into the early moments of a human life; and a pilot plant in the heart of Texas’s petrochemical industry is attempting to create completely clean power from natural gas—probably a major energy source for the foreseeable future. These and the rest of our list will be worth keeping an eye on. —The Editors

3-D Metal Printing

While 3-D printing has been around for decades, it has remained largely in the domain of hobbyists and designers producing one-off prototypes. And printing objects with anything other than plastics—in particular, metal—has been expensive and painfully slow.

Now, however, it’s becoming cheap and easy enough to be a potentially practical way of manufacturing parts. If widely adopted, it could change the way we mass-produce many products.3.

In the short term, manufacturers wouldn’t need to maintain large inventories—they could simply print an object, such as a replacement part for an aging car, whenever someone needs it.

In the longer term, large factories that mass-produce a limited range of parts might be replaced by smaller ones that make a wider variety, adapting to customers’ changing needs.

The technology can create lighter, stronger parts, and complex shapes that aren’t possible with conventional metal fabrication methods. It can also provide more precise control of the microstructure of metals. In 2017, researchers from the Lawrence Livermore National Laboratory announced they had developed a 3-D-printing method for creating stainless-steel parts twice as strong as traditionally made ones.

Also in 2017, 3-D-printing company Markforged, a small startup based outside Boston, released the first 3-D metal printer for under $100,000.

Another Boston-area startup, Desktop Metal, began to ship its first metal prototyping machines in December 2017. It plans to begin selling larger machines, designed for manufacturing, that are 100 times faster than older metal printing methods.

The printing of metal parts is also getting easier. Desktop Metal now offers software that generates designs ready for 3-D printing. Users tell the program the specs of the object they want to print, and the software produces a computer model suitable for printing.

GE, which has long been a proponent of using 3-D printing in its aviation products (see “10 Breakthrough Technologies of 2013: Additive Manufacturing”), has a test version of its new metal printer that is fast enough to make large parts. The company plans to begin selling the printer in 2018. —Erin Winick

Sensing City

Numerous smart-city schemes have run into delays, dialed down their ambitious goals, or priced out everyone except the super-wealthy. A new project in Toronto, called Quayside, is hoping to change that pattern of failures by rethinking an urban neighborhood from the ground up and rebuilding it around the latest digital technologies.

Alphabet’s Sidewalk Labs, based in New York City, is collaborating with the Canadian government on the high-tech project, slated for Toronto’s industrial waterfront.

One of the project’s goals is to base decisions about design, policy, and technology on information from an extensive network of sensors that gather data on everything from air quality to noise levels to people’s activities.

The plan calls for all vehicles to be autonomous and shared. Robots will roam underground doing menial chores like delivering the mail. Sidewalk Labs says it will open access to the software and systems it’s creating so other companies can build services on top of them, much as people build apps for mobile phones.

The company intends to closely monitor public infrastructure, and this has raised concerns about data governance and privacy. But Sidewalk Labs believes it can work with the community and the local government to alleviate those worries.

“What’s distinctive about what we’re trying to do in Quayside is that the project is not only extraordinarily ambitious but also has a certain amount of humility,” says Rit Aggarwala, the executive in charge of Sidewalk Labs’ urban-systems planning. That humility may help Quayside avoid the pitfalls that have plagued previous smart-city initiatives.

Other North American cities are already clamoring to be next on Sidewalk Labs’ list, according to Waterfront Toronto, the public agency overseeing Quayside’s development. “San Francisco, Denver, Los Angeles, and Boston have all called asking for introductions,” says the agency’s CEO, Will Fleissig. —Elizabeth Woyke

5.

Dueling Neural Networks

...MUCH MORE

HT it was out: de zeen