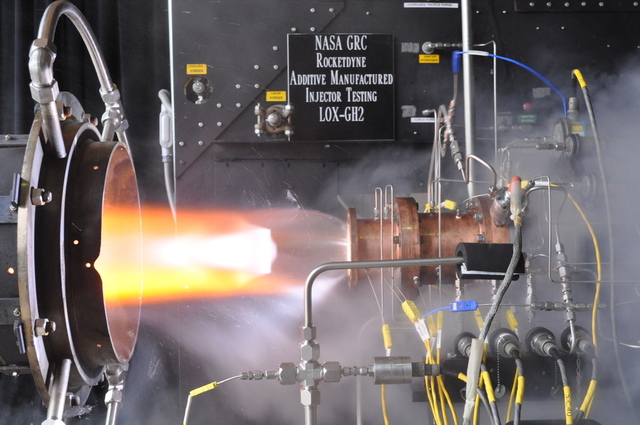

NASA has successfully tested its first rocket engine component made through 3D printing. On Thursday, NASA subjected its new rocket engine injector to a series of high-pressure fire tests involving liquid oxygen and gaseous hydrogen, demonstrating that additive manufacturing (its official name) could one day help the agency build the next generation of rockets faster and at lower cost.Additive manufacturing uses layers of metallic powder traced in specific patterns by lasers. The technique isn't too far removed from traditional 3D printing, except it uses high-powered laser beams. While an engine injector is normally one of the most expensive components of a rocket engine to produce, additive manufacturing not only reduces development time from over a year to a number of months, it also cuts costs by more than 70 percent. Following the successful test, NASA says it will look to scale-up and establish production requirements for the injector, helping it "demonstrate the feasibility of developing full-size, additively manufactured parts." However, the agency says has no plans to test its printed components in a live test flight until 2017.